QuEChERS, which stands for Quick, Easy, Cheap, Effective, Rugged, and Safe, is a popular sample preparation technique used in analytical chemistry, particularly in the analysis of pesticides, herbicides, and other contaminants in food and environmental samples. This method was developed to streamline the sample preparation process, making it quicker, more cost-effective, and safer while maintaining high analytical accuracy and sensitivity.

The key features of the QuEChERS technique are:

Quick: QuEChERS offers a rapid and efficient sample preparation process compared to traditional methods. It significantly reduces the time required for sample extraction and cleanup.

Easy: The technique is straightforward and easy to perform, making it accessible to both experienced analysts and those new to the field.

Cheap: QuEChERS utilizes relatively inexpensive and readily available materials for sample extraction and cleanup, which reduces the overall cost of analysis.

Effective: Despite its simplicity, QuEChERS provides high recovery and accuracy for a wide range of analytes, making it a reliable method for quantitative analysis.

Rugged: The method is robust and applicable to various sample types and analytes, ensuring consistent results even with complex matrices.

Safe: QuEChERS minimizes the use of hazardous chemicals, making it safer for laboratory personnel and the environment.

The QuEChERS method typically involves three steps:

Step 1: Homogenization

- Cut sample into smaller portion and freeze before homogenization.

- Recommended to homogenize frozen samples with dry ice or liquid nitrogen.

- Sample can be more homogenized evenly and fine (larger surface area for extraction)

- Minimize degradation and volatile losses of certain pesticides.

- Make sure all dry ice sublimed before weighing samples.

- Ensure water condensation is minimal.

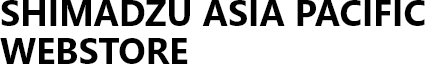

Step 2: Extraction

The extraction step in QuEChERS is the process of removing the target analytes from the complex sample matrix using a solvent mixture. The objective is to selectively dissolve the analytes of interest into the solvent while leaving unwanted matrix components behind.

|

AOAC 2007.01 Method

|

EN 15662 Method

|

|

|---|---|---|

| Step 1 |

Weigh 15 g homogenized sample in 50mL centrifuge tube.

|

Weigh 10 g homogenized sample in 50mL centrifuge tube.

|

| Step 2 |

Add 15 mL ACN with 1% HOAc and shake for 1 min.

|

Add 10 mL ACN and shake for 1 min.

|

| Step 3 |

Add 6 g anh. MgSO4 + 1.5 g anh. NaOAc quickly

(P/N: 380-00152)

|

Add 4 g anh. MgSO4 + 1 g NaCl + 1 g TSCD + 0.5 g DHS quickly

(P/N: 380-00149)

|

| Step 4 |

Shake vigorously for 1 min. Then centrifuge >1500 rcf for 1 min.

|

Shake vigorously for 1 min. Then centrifuge >3000 rcf for 5 min.

|

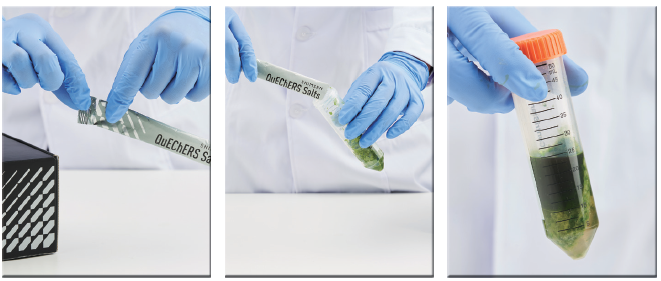

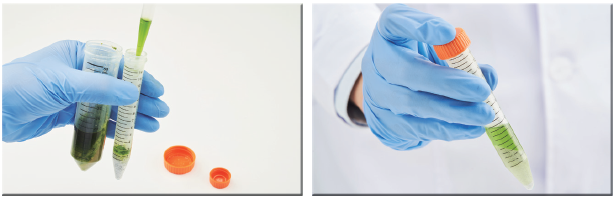

Step 3: Clean-up

The cleanup process is a critical step that follows the extraction of target analytes from the sample matrix. The objective of this step is to remove unwanted matrix components, interfering substances, and co-extracted impurities that could potentially affect the accuracy and sensitivity of the analytical method. Cleaning up the extract enhances the quality of the final data and minimizes matrix effects during analysis.

|

AOAC 2007.01 Method

|

EN 15662 Method

|

|

|---|---|---|

| Step 1 |

Transfer 1 or 8 mL of extract to centrifuge tube containing appropriate dSPE.

|

Transfer 1 or 6 mL of extract to centrifuge tube containing appropriate dSPE.

|

| Step 2 |

Shake for 30 sec and centrifuge >1500 rcf for 1 min.

|

Shake for 30 sec and centrifuge >3000 rcf for 5 min.

|

| Step 3 |

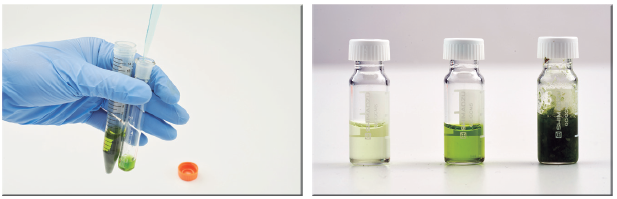

Filter by syringe filter

|

Filter by syringe filter

|

Dispersive solid-phase extraction (dSPE) involves the use of specific sorbents to selectively adsorb and retain unwanted compounds, leaving the target analytes in the solution for further analysis.

Below are different types of dSPE and their functions:

|

dSPE components

|

Functions |

|---|---|

|

Magnesium Sulfate (MgSO4)

|

Remove excess water

|

|

Primary Secondary Amine (PSA)

|

Remove sugar, fatty acids, organic acids, anthocyanine.

|

| C18 |

Removes lipids, non-polar substances.

|

|

Graphitized Carbon Black (GCB)

|

Remove pigments, sterols, non-polar substances.

*Also removes planar molecules.

|

| Type | dSPE Vol. | AOAC 2007.01 Method | EN 15662 Method |

|---|---|---|---|

|

General Fruits & Vegetables

|

2mL |

50 mg PSA, 150 mg MgSO4 P/N: 380-00990-17 |

25 mg PSA, 150 mg MgSO4 P/N: 380-00990-21 |

| 15mL |

400 mg PSA, 1200 mg MgSO4 P/N: 380-00990-05 |

150 mg PSA, 900 mg MgSO4 P/N: 380-00990-02 |

|

|

Food with Fats and Waxes

|

2mL |

50 mg PSA, 50 mg C18, 150 mg MgSO4 P/N: 380-00990-18 |

25 mg PSA, 25 mg C18,150 mg MgSO4 P/N: 380-00990-22 |

| 15mL |

400 mg PSA, 400 mg C18, 1200 mg MgSO4 P/N: 380-00990-07 |

150 mg PSA, 150 mg C18, 900 mg MgSO4 P/N: 380-00990-06 |

|

|

Pigmented Fruits & Vegetables

|

2mL |

50 mg PSA, 50 mg C18, 50 mg GCB, 150 mg MgSO4 P/N: 380-00990-20 |

25 mg PSA, 2.5 mg GCB, 150 mg MgSO4 P/N: 380-00990-23 |

| 15mL |

400 mg PSA, 400 mg C18, 400 mg GCB, 1200 mg MgSO4 P/N: 380-00990-08 |

150 mg PSA, 15 mg GCB, 900 mg MgSO4 P/N: 380-00990-17 |

|

|

Highly Pigmented Fruits & Vegetables

|

2mL |

25 mg PSA, 7.5 mg GCB, 150 mg MgSO4 P/N: 380-00990-24 |

|

| 15mL |

150 mg PSA, 45 mg GCB, 900 mg MgSO4 P/N: 380-00990-04 |